Pre-Engineered Fire Suppression Systems

Pre-Engineered Fire Suppression Systems

Pre-engineered fire suppression systems provide immediate response to fire during the initial critical minutes. There are two common types of systems:

Dry Chemical Systems

Dry chemical fire suppression systems use dry chemical compounds that suppress fire effectively and provide efficient coverage. They are easy to install and maintain in any industrial setting. They require recharging after operation. Dry chemical agents come in ABC or BC. In applications where a dedicated water supply is not available, dry chemical is an easy, affordable alternative to water and some other agents.

Dry chemical systems must comply with NFPA 17 – Standard for Dry Chemical Extinguishing Systems and NFPA 33 – Standards for Spray Application Using Flammable and Combustible Materials, and also be tested to the new real-world criteria of UL 1254 – Standard for Safety Pre-Engineered Dry and Wet Chemical Extinguishing System Units.

Wet Chemical Systems

A wet agent system is an effective way for suppressing commercial cooking fires before major damage occurs. When a wet chemical agent is applied in a concentrated liquid spray to a burning surface, it reacts quickly with the cooking media (fats or oils) to produce a foam blanket covering the surface. This reaction, combined with the cooling effect of the wet chemical agent, also reduces the possibility of fire re-flash.

Wet Chemical Systems must comply with the NFPA 17A – Standard for Wet Chemical Extinguishing Systems and NFPA 96 – Standard for Ventilation Control and Fire Protection for Commercial Cooking Operations, and also be tested and listed to UL 300 – Standard for Fire Testing of Fire Extinguishing Systems for Protection of Commercial Cooking Equipment.

Benefits

Early detection and quick response

Pre-engineered fire suppression systems provide fast, on-site protection at the earliest stage of a fire. Depending upon the detection package installed, the system response could be immediate or time delayed.

Safe and easy to use

Since pre-engineered fire suppression systems activate automatically, they are safe and easy to use. Systems do not require human intervention although they do provide a manual override option in case of emergency.

Pre-engineered and tested to ensure success

Designed in accordance with NFPA standards and tested to stringent Underwriters Laboratories Inc. (UL) testing protocols, pre-engineered fire suppression systems are pre-tested to effectively extinguish specific types of fires in special hazard situations.

Eliminates fuel source

The fuel or electrical source of a fire contained within cooking equipment often continues to feed the fire after it has ignited. Pre-engineered fire suppression systems eliminate the heat source automatically.

Proper Operation

Pre-engineered fire suppression systems are typically required in the following facilities:

- Restaurants

- Paint Spray Booths

- Collision and Auto Repair Facilities

- Auto Dealerships

- Hospitals

- Institutions

- Culinary Arts Training Facilities

- Nursing Homes

- Educational Facilities

- Industrial Coating and Dip Tanks

- Flammable/Combustible Storage Areas

NFPA Standards—such as 17, 17A, 33, 34 and 96—specify Special Hazard Situations where Pre-Engineered Systems are mandated. This includes situations with:

- Flammable or combustible liquids or gases

- Paint spray operations involving flammable or combustible materials

- Combustible solids, such as plastics

- Electrical hazards, such as oil-filled transformers or circuit breakers

- Textile operations subject to flash surface fires

- Ordinary combustibles, such as wood, paper or cloth

- Restaurant and commercial hoods, ducts and associated cooking appliance hazards, such as deep-fat fryers

- Data centers and electrical storage rooms

- Turbines

- Automobile refueling areas

Inspection & Maintenance

The following lists include items that should be regularly monitored and maintained monthly for both of the common pre-engineered fire suppression systems:

Dry Chemical Systems

- Make sure inspection tag is current

- Make sure there is no obvious mechanical damage to cylinder piping or nozzles

- Check positioning of all nozzles

- Check if tamper seals are intact and for any evidence of tampering

- If system has been discharged, report

- Make sure proper nozzle covers in place

- Make sure fuel is shut-off

- Check if portable extinguishers are available, accessible and operational

- Ensure manual pull-stations are labeled and accessible

Additional service and maintenance are required in accordance with manufacturers’ instruction manual.

Wet Chemical Systems

- Make sure inspection tag is current

- Make sure there is no obvious mechanical damage to cylinder piping or nozzles

- Check positioning of all nozzles

- Check if tamper seals are intact or for any evidence of tampering

- If system has been discharged, report

- Make sure proper nozzle covers in place

- Make sure exhaust fan is in operating order

- Make sure fuel shut-off is in on position

- Check if portable extinguishers are properly accessible

- Ensure manual pull-stations are labeled and accessible

Additional service and maintenance may be required in accordance with manufacturers’ instruction manual.

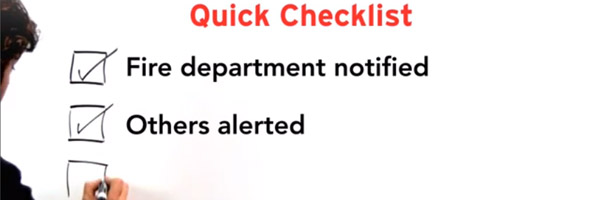

Fire Inspectors

The following checklist can be used by fire inspectors out in the field inspecting pre-engineered fire suppression systems as a guide for ensuring that safe, effective, and up-to-date systems exist. Don’t forget to also refer to the manufacturer’s specific installation and maintenance manuals.

Dry Chemical Systems — Industrial Protection

- Inspection tag and maintenance report is up to date

- All hazards properly covered with correct nozzles

- Duct and plenum covered with correct nozzles

- Check positioning of all nozzles

- System installed in accordance with MFG UL listing

- Penetrations sealed with weld or UL listed device

- Check if seals are intact and for evidence of tampering

- If system has been discharged, report same

- Pressure gauge in proper range (if applicable)

- Inspect cylinder and mount

- Proper nozzle covers in place

- Piping and conduit securely bracketed

- Manual and remote set/seals intact

- System protective hardware covers in place

- Proper hand portable extinguishers

- Portable extinguishers available, accessible and properly serviced

- Class K portable extinguisher in place (if required)

Don’t forget to refer to the manufacturer’s specific installation and maintenance manuals.

Wet Chemical Systems — Commercial Cooking Area Protection

- Inspection tag and maintenance report is up to date

- All hazards are properly covered with correct nozzles

- Duct and plenum covered with correct nozzles

- Check positioning on all nozzles

- System installed in accordance with MFG UL listing

- Penetrations sealed with weld or UL listed device

- Check if seals are intact, and for evidence of tampering

- If system has been discharged, report same

- Pressure gauge in proper range (if applicable)

- Inspect cylinder and mount

- Proper nozzle covers in place

- Piping and conduit securely bracketed

- Proper separation between fryers and flame

- Proper clearance from flame to filters

- Exhaust fan in operating order

- All filters are in place

- Manual and remote set/seals intact

- System protective hardware covers in place

- Fan warning sign on hood

- Proper hand portable extinguishers

- Portable extinguishers available, accessible and properly serviced

- Class K portable extinguisher in place (if required)

Don’t forget to refer to the manufacturer’s specific installation and maintenance manuals.

Learn More and Test Your Knowledge

Test your knowledge about fire safety and fire protection equipment. How much do you know?

View fire safety infographics created by the Fire Equipment Manufacturers’ Association.

Watch fire safety videos produced by the Fire Equipment Manufacturers’ Association.

| Why It’s Important to Use Manufacturer Recommended Parts for Pre-Engineered Systems (PDF) Understand the performance, reliability, warranty and listing concerns associated with “non-complying parts” for pre-engineered systems. |

|

| Decision Tree for Servicing Pre-Engineered Systems in Commercial Cooking Operations (PDF) Determine whether your pre-engineered system should be serviced or replaced with a UL 300 listed system. |

|

| Recommended Practice on Upgrading Restaurant Cooking Area Fire Protection Systems (PDF) Understand why the UL 300 Standard was revised and what impact the changes have on existing systems. |

|

| Lack of UL 300 System Negates Restaurant’s Fire Insurance Policy (PDF) Court case backs the need for replacing an existing dry chemical system with a code-compliant UL 300 wet chemical system. |

|

| Restaurant Fire Protection – UL 300 (PDF) Test your knowledge of UL Standard 300. |

|

| Discharging Wet Chemical Agent When Performing an Acceptance Test (PDF) The Fire Equipment Manufacturers’ Association opposes discharging extinguishing agent when performing a full system discharge test for the installation approval of a pre-engineered wet chemical suppression system. |

|

| Find Out How UL 1254 Changes the Way Industrial Hazards are Protected (PDF) Understand the reasoning, changes, and effects of the revised UL 1254 Standard. |

|

| FEMA Recommendations for Protection of Curtained Limited Finishing Workstations (PDF) FEMA recommendations are based upon live fire testing of prep stations utilizing one or more vinyl curtain walls. |

|

| Third-Party Training for Fire Suppression Systems (PDF) A Fire Equipment Manufacturers’ Association advisory concerning the acceptability of third-party training for pre-engineered fire suppression systems. |