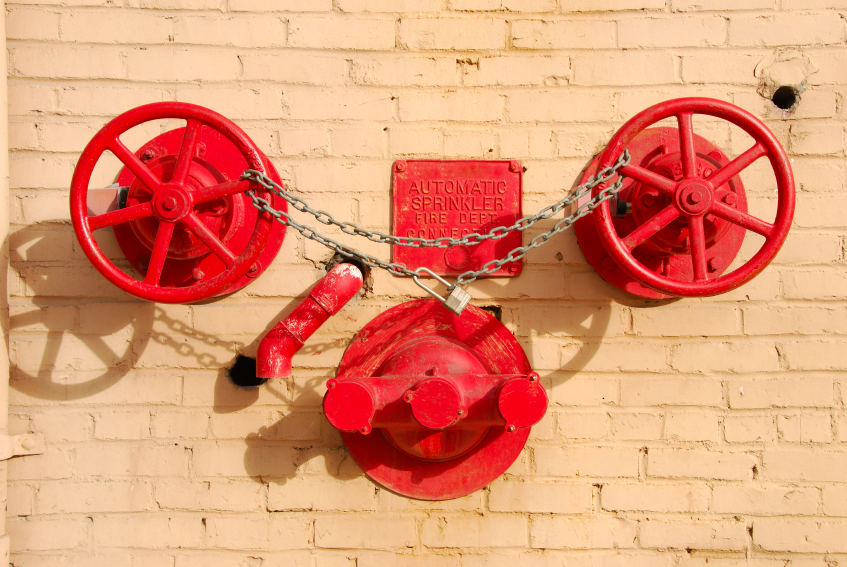

Fire Hose, Cabinets & Valves

About Standpipe Fire Hose Stations

Standpipe fire hose stations provide quick response during the first few minutes.

Standpipe and rack hose systems provide means for manual application of water to fires in buildings. They do not take the place of automatic extinguishing systems, which are important in large buildings.

Quick Suppression

Standpipe hose systems can be effectively used in the incipient stage (after everyone is safe and the fire department has been called), often extinguishing the fire before automatic systems can activate.

One Person Operation

Standpipe hose systems are activated and operated by one person, and do not depend on heat, smoke or flame to spread before water is applied to the fire. This manual equipment provides total reliability in case automatic systems fail.

Minimal Water Damage

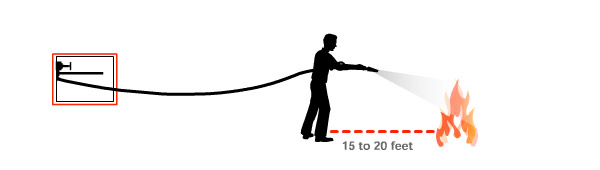

Standpipe hose systems can minimize water damage since water can be applied directly at the base of the fire versus indiscriminate spray from automatic systems. Additionally, the hose systems can be turned off immediately.

Occupancy Safety & Rescue

Standpipe hose systems can be used to allow time for evacuation, protect a means of egress, or defend occupants who cannot evacuate the building.

Classes of Standpipes

The Three Types of Standpipe Systems

Class I Systems

Class I Systems [2-1/2″ (64 mm) hose connections] are provided for use by fire departments and those trained in handling heavy water streams. In high rise buildings without sprinklers and beyond the reach of fire department ladders, Class I systems provide water supply for the primary means of firefighting, i.e. manually.

Class II Systems

Class II Systems [1-1/2″ (38 mm) hose lines] are provided for use by trained building occupants until the fire department arrives.

Class III Systems

Class III Systems shall provide [1-1/2″ (38 mm)] hose stations to supply water for use by trained building occupants and [2-1/2″ (64 mm)] hose connections to supply a larger volume of water for use by fire departments and those trained in handling heavy water streams.

Proper Use

Proper Standpipe Use

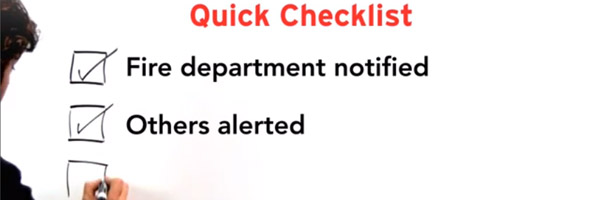

Remember, only fight a fire when:

1. The fire department has been called.

2. Everyone is safe.

3. The fire is small and does not appear to be spreading.

4. The fire is not between you and the exit.

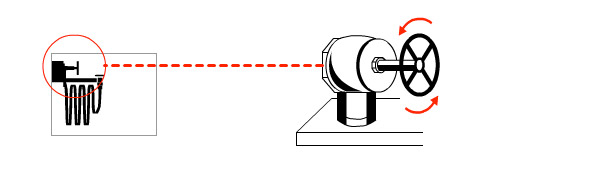

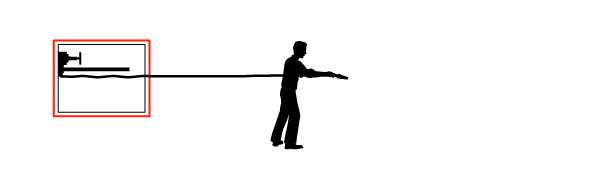

1. Open valve completely.

2. Pull hose entirely off rack (or else water will not flow).

3. Open nozzle. Water will flow when hose is entirely off rack and nozzle is open.

Inspection & Maintenance

Fire hose stations should usually be inspected or checked every 90 days (or as specified by local AHJ). The business owners or building occupants are responsible for making sure that the fire hose station is regularly checked and maintained. Fire hose stations will not be an effective fire-fighting tool if they are not properly maintained and inspected for quality assurance.

Review the checklist below to identify key concerns with the fire equipment and contact local fire authorities if a repair is needed.

- Are the operating instructions legible?

- Does the cabinet appear to be intact with no cracks or breaks in the glass?

- Is the cabinet door easy to open?

- If a locked cabinet is installed, does the lock function properly?

- Will the hose rack swing out at least 90° from the cabinet?

- Are any safety seals broken or missing?

- Is there any obvious damage or corrosion to the hose valve?

- Is the valve handle missing?

- Does the hose appear to be folded neatly on the hose rack?

- Is the hose connected to the rack nipple or valve?

- Is the hose intact with no breaks, holes, or tears?

- Is the hose nozzle missing?

- Are all warning labels and tags free from damage?

- Are all the valves, hose nozzles, fire extinguishers, etc. easily accessible?

Consult NFPA 25 Tables 6.1 and 6.22 or your local fire department for more information about standpipe fire hose station inspection and maintenance.

Pressure Reducing Valves: Understanding the Requirements and Impact of Firefighting Operations

Watch an on-demand webinar to learn about pressure reducing valve (PRV) requirements and see how PRVs impact firefighting operations. The webinar answers the following questions:

- What are pressure reducing valves?

- Where are they required?

- Why are they required?

- How do they operate?

- Are they important to fire suppression operations?

The Fire Equipment Manufacturers’ Association participated in this webinar, which was produced by UL in partnership with the International Association of Fire Chiefs and the International Association of Fire Fighters.

Learn More and Test Your Knowledge

Test your knowledge about fire safety and fire protection equipment. How much do you know?

View fire safety infographics created by the Fire Equipment Manufacturers’ Association.

Watch fire safety videos produced by the Fire Equipment Manufacturers’ Association.

| The Evolution of Fire Hose (PDF)

An overview of the history, benefits and standards of modern fire hose.

|

|

| High-Rise Fire Protection: A Tall Order (PDF)

Understand potential fire risks, and learn about critical life-saving equipment, for high-rise buildings. |

|

| Rack and Reel Fire Hose Ensure Dependability (PDF)

Simple steps to maintain and replace rack and reel hoses. |

|

| Fire Hose Rack Inspection Guidelines (PDF) Maintenance guidelines and inspection protocol for standpipe rack hose stations. |

|

| A Closer Look: Standpipe Fire Hose Stations (PDF)

Understand the benefits and proper use of standpipe rack hose stations as part of a layered fire protection plan. |